Layer separation mechanism is one of the most important factor that determines the performance of a bottom-up high resolution SLA 3D printer. Therefore, the resin container is also one of the most important part of a bottom-up high resolution SLA 3D printer. Kudo3D uses a US patented PSP technology to minimize the force required to separate cured layers. This blog will help you understand the different parts of the PSP resin container, how it works, and how to extend the lifetime.

What is a PSP Resin Container?

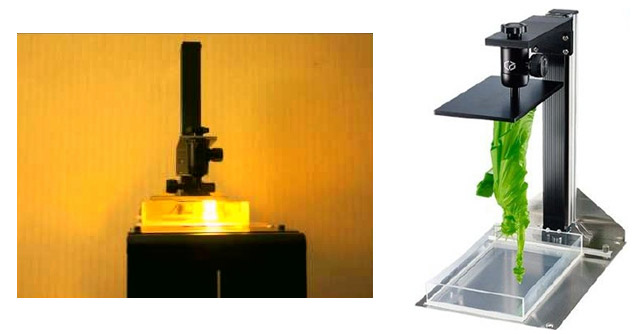

PSP stands for Passive Self-Peeling. This is the key component to the “secret” of Kudo3D’s high-resolution 3D printer. Instead of forcibly pulling the printed layers apart from the vat floor, the flexible PSP resin container greatly reduces the separation force between each layer by passively peeling it apart. There is no extra motor to pull the container away and the bending of the container mimics the action of peeling a piece of tape away from a hard surface. This greatly reduces the separation force and thus results in a faster speed as well as the ability to print large models and fine details compared to other types of layer separation mechanism. The vat floor is formed with a layer of elastic clear silicone to assist in peeling. It is well known that clear silicone tends to react with resins and become cloudy after one or two prints on the same spot. Depending on the resin used and number of layers in a model, silicone could permanently bond with the cured layer when reacting with the resins. Therefore, we cover the silicone with a thin layer of Teflon to protect the silicone. By doing so, the lifetime of the container is greatly extended.

Brief History of Kudo3D’s Different Generations of PSP Resin Container

First Generation to Third Generation Resin Container.

During Kudo3D’s Kickstarter campaign, back in May 2014, we released the first generation of PSP resin container along with the Titan 1. It was a fairly simple design: acrylic container with silicone and Teflon, along with 2 thin plastic side walls. These side walls were first held together with double sided tape and sealed with silicone. Though it fulfilled everything that it promised, there was a slight problem with this container. When the container is lifted too much, the silicone sealant may not work. The resin may get to the adhesive through the gap between the silicone and the side walls. The resin weakened the holding between the side walls and resulted in a leakage after using for a while. Although first generation container has such a problem, it was easy for DIYers to make it by themselves.

Upon learning this, our team quickly found a solution to this problem. Using a stronger chemical bonding to replace double sided tape, we released the second generation of PSP resin container. The interface between the side walls and the acrylic is strong to prevent the resin from seeping through. However, we soon found that 3D-Materials resin could react with the side wall materials and cut through the side walls gradually. The side walls lasted about 120 hours if the container was maintained properly. The 3D-Material resin users experienced a lower resin container lifetime that ultimately could led to leaking containers- if not caught early on.

To extend the lifetime, 3D-Material resin users needed to clean up the container after each use and must monitor the sidewall condition. When using non-3DM materials, the lifetime was much longer for the second generation PSP containers.

To be more compatible with 3DM resins, the PSP resin containers went through another round of testing and development in order to identify a material that resists 3DM resins while still be chemically bonded to the acrylic. Finally, Kudo3D’s R&D team was able to create the third generation of PSP resin container, our current generation, which is deemed “all-resin safe.” We are happy to state that we have been accident-free of leaking resin containers since the release of it over a year ago!

Soft Silicone? Hard Silicone?

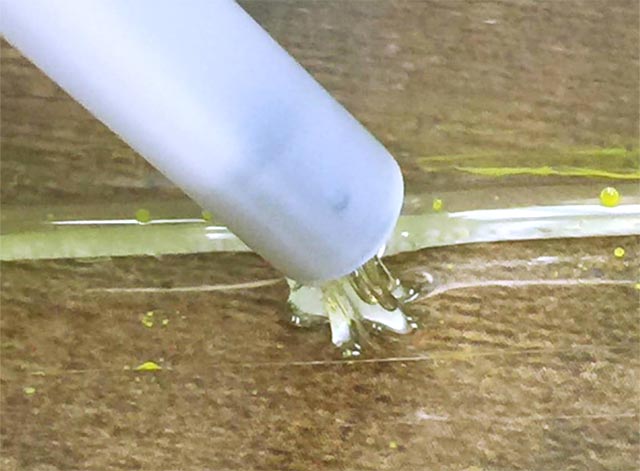

Do you see the stickiness of the soft silicone?

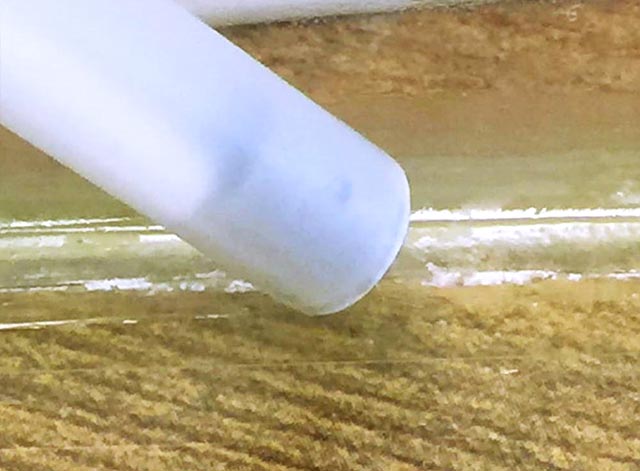

But not for the hard silicone!

As you may notice, we offer two types of resin container: soft silicone resin containers and hard silicone resin containers. However, what exactly is the difference and how do you know when to use which type of silicone?

The soft silicone resin container, as the name states, uses a soft silicone with a Teflon sheet on top of the silicone. The adhesion force between the Teflon and silicone is much higher than of the hard silicone. The silicone is extremely sticky. If you touch the silicone (which we do not recommend unless necessary), the silicone will stick to your finger and stretch out, almost like when you try to pull gum off your shoe. This soft silicone resin container is very useful when printing smaller objects, such as rings or miniatures. The separation force, when using this resin container, is much lower and is generally recommended for first time users. The downside of this resin container is that the Teflon film is more susceptible to warpage and is not ideal for larger prints and prints require flat surfaces.

The hard silicone resin container uses a hard silicone and a Teflon film on top. The adhesion force between the Teflon and the silicone is much lower than of the soft silicone. If you were to touch the surface, the surface will feel tougher and will not come up along with the finger. Unlike the soft silicone resin container, the Teflon film on the hard silicone resin container will have less warpage, and users are able to print large objects or objects with a flat surface. The downside is that users will need to print at a lower printing speed, due to the higher separation force.

How Do You Maximize the PSP Resin Container Lifetime?

Although the silicone is protected by the Teflon to increase the lifetime of the container, the Teflon film itself still has a lifetime which is dependent on the separation force. Teflon film starts warping after experiencing a high separation force. Since Teflon and silicone are the two most chemically resistant materials, there is no way to permanently bond them together. Severe warpage could induce a gap between the Teflon film and silicone. The resin can enter through the gap and separate the Teflon from the silicone. If the silicone is not damaged, it is possible to replace the Teflon film. For hard silicone, you would need to use a clear double sided tape to bond a new film. For soft silicone, you would need to peel off the Teflon film gently to avoid damaging the silicone, and lay a new film down slowly to prevent dusts or bubbles from getting in-between. For details, please refer to our forum.

To maximize the PSP container lifetime, users must minimize the separation force and avoid model dropping. Please refer to Printing Guide to prevent model dropping. The shrinkage of the cured model could introduce warpage on the Teflon film. When the adhesion between the cured layer and the Teflon is larger, the front of the container will be lifted. If the container is lifted over 5 mm before dropping back down onto the frame, you may need to reorient the model and make some adjustment to the printing parameters. The height being lifted is a good indicator of the separation force.

There are many factors that has an impact on the separation force and thus the lifetime of a resin container:

- Exposed area of a slice (reduce cross-sectional area)

- Pattern of the layer (avoid circle and square patterns that are hard to separate)

- Orientation of the print (avoid printing same pattern on the same spot)

- Lifting speed (lower speed reduces separation force)

- Exposure time (less exposure has less adhesion to the Teflon)

- Reactivity of the resin (when the resin temperature is higher, the film is more likely to warp)

- Native adhesion between cured resin and Teflon caused by the Van Der Waals’ force (use resins with less adhesion)

- Layer thickness (thinner layer with less exposure has also less adhesion to the Teflon)

The golden rule to elongating the lifetime of your resin container is:

Once you understand how to minimize the separation force, it is quite possible to use a single PSP resin container for more than 100 prints. Take it slow and try to understand more about not only Kudo3D’s printer but also about its printing process involved. This will allow you to have a much more successful print.

Leave A Comment