Being one of the core components in the 4th industrial revolution, 3D printing has evolved in such an astonishing speed. However, the technology behind each printer is so diverted that some of the first time users or those who want to get their very first 3D printer might not be that confident in identifying the best one for themselves. Today, we would like to walk you through this latest rapid prototyping technology and explain why Kudo3D’s printers are so unique and get so much attentions from the jewelry, dental, medical, academics and rapid prototyping industries all over the world.

Many of the consumer level printers were FDM (Fused Deposition Modeling) 3D printers. This involved a spool of filament to be heated to a high temperature and deposited into the shape that the user wishes to create via an extrusion head. With this type of printer, users only get the shape or form of the print but will not get details nor reach surface smoothness. In addition, the printing speed is relatively low.

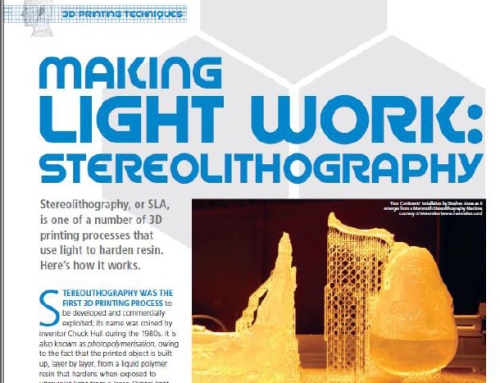

Apart from the FDM technology, some 3D printers adopts the stereolithography (SLA) technology. Some SLA 3D printers use laser galvanometer to create patterns. This type of printer usually has laser stability and reliability problems.

How about the Titan 1 and Titan 2? Instead of the laser-based SLA technology, we use Kudo3D uses a highly reliable DLP technology developed by Texas Instrument to generate digital light patterns in a two dimensional fashion rather than scanning with a laser diode which is susceptible to ambient temperature, dusts and mechanical failure. DLP can also provide a resolution that laser galvanometer is impossible to match.

Using a better digital light pattern generator improves the resolution of the printers but it is not the main factor that attributes to our success in the last two years. So what exactly set our 3D printer apart from the other SLA 3D printers out in the market? The answer lies within the layer separation technology of the printer.

Most low cost SLA printers incorporate a bottom up light source and a transparent resin container. The challenge to these SLA printers is to separate the cured layer from the resin container floor. The separation force is proportional to the area of the cured layer. That is why most of the low cost SLA is not able to print big models.

To overcome this challenge, we have developed a patent pending passive self-peeling (PSP) technology that greatly reduces the separation force that others are hard to match by using both flexible and elastic materials for the resin container. PSP not only enables large area printing but also increases the speed and resolution of the prints. Since the peeling is passive, there are no motors involved. The printer’s structure is simplified. With less moving parts, the Titan 1 and Titan 2 are very reliable.

We understands that the lifetime of the consumables is a main concern for consumers while resin container is definitely a critical part for low cost SLA printers. Because of the low separation force, our container is less stressed and the lifetime is much longer. Besides, there is a protective film on the vat floor of Kudo3D’s containers to prevent the attack from the resin. As a result, our printers are compatible with more materials and relax the constraint for material developers.

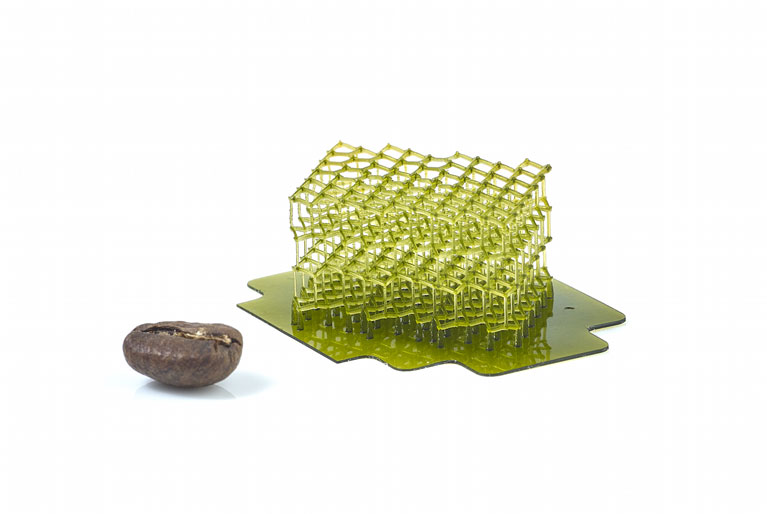

With the PSP technology, Titan 1, our first generation printer, proved its worth when Kudo3D showed off a biomedical tissue scaffold research model printed at 37 micron XY resolution and 20 micron Z layer thickness. The beams have a diameter of 0.18mm (next to the print is a coffee bean for scale).

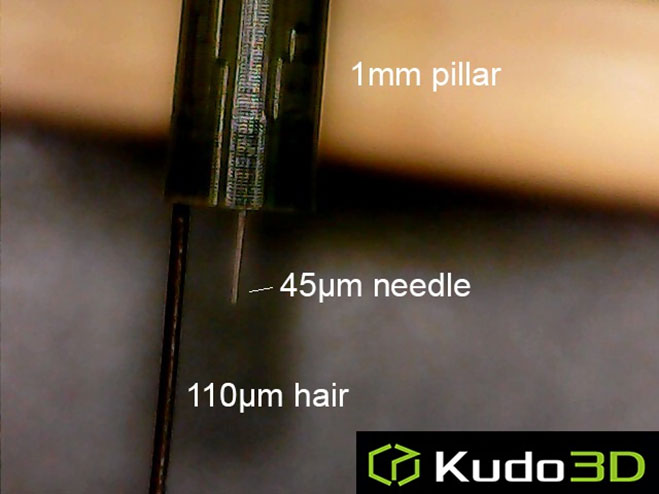

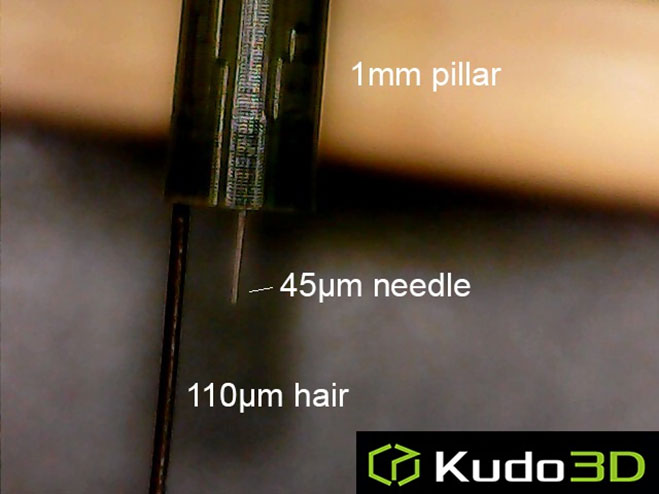

Pushing the printer to the extreme, we proved once more that our printers can print fine features that other low cost SLA printers cannot achieve. In the image below, a 45 micron thin needle was printed with the Titan 1. This needle is less than half the diameter of a hair. No other low cost printer can achieve this resolution.

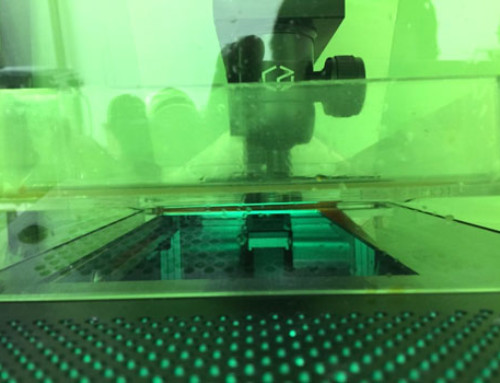

Now in June 2016, we have launched its second-generation 3D printer, the Titan 2.

The new Titan 2 features:

- WiFi enabled.

– There is no need to connect the printer to the computer after uploading the data. - Allows web-based controlling.

– Users can use any device (PC, Mac, smartphones, or tablet) to control the printer. Once the printing starts, the control device can be used for other purposes. - One device can be used to command and control multiple Titan 2 3D printers.

– This is especially helpful for those who would like to use the printer to setup a production line. - Has a built-in computer.

– The Titan 2 will be independent from the user’s computer. - Has a shutter to reduce background exposure during prints.

– This can ensure high quality prints.

Additionally, the new Titan 2 will be assembled and calibrated before shipping, making the startup process even easier for first time users.

It is definite that 3D printer will keep evolving in technological advancement. Users are now able to print high quality things that they design or even better than they could ever imagined.

Leave A Comment